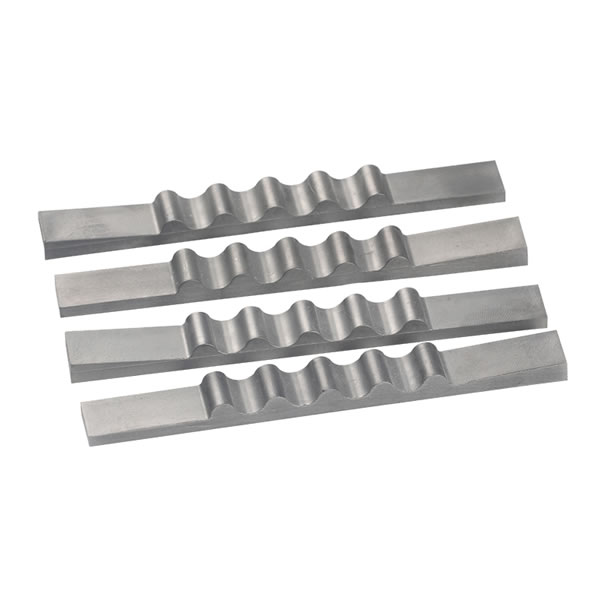

Product Name: Hardness HRA94 Carbide wear parts

Hardness 93-94,

Size: 90x10x5mm

ISO K10F grade

Density 14.95g / cm3

Grain size 0.8 micrometer.

Description:

This kind of products require a high technical during production, in order to control the size, arc and the interval between each teeth. In the mean time, the hardness is much higher than standard items.

The hardness is around HRA93-94.

Also, there are different shape, different teeth as customer’s requirements. You can see as follows:

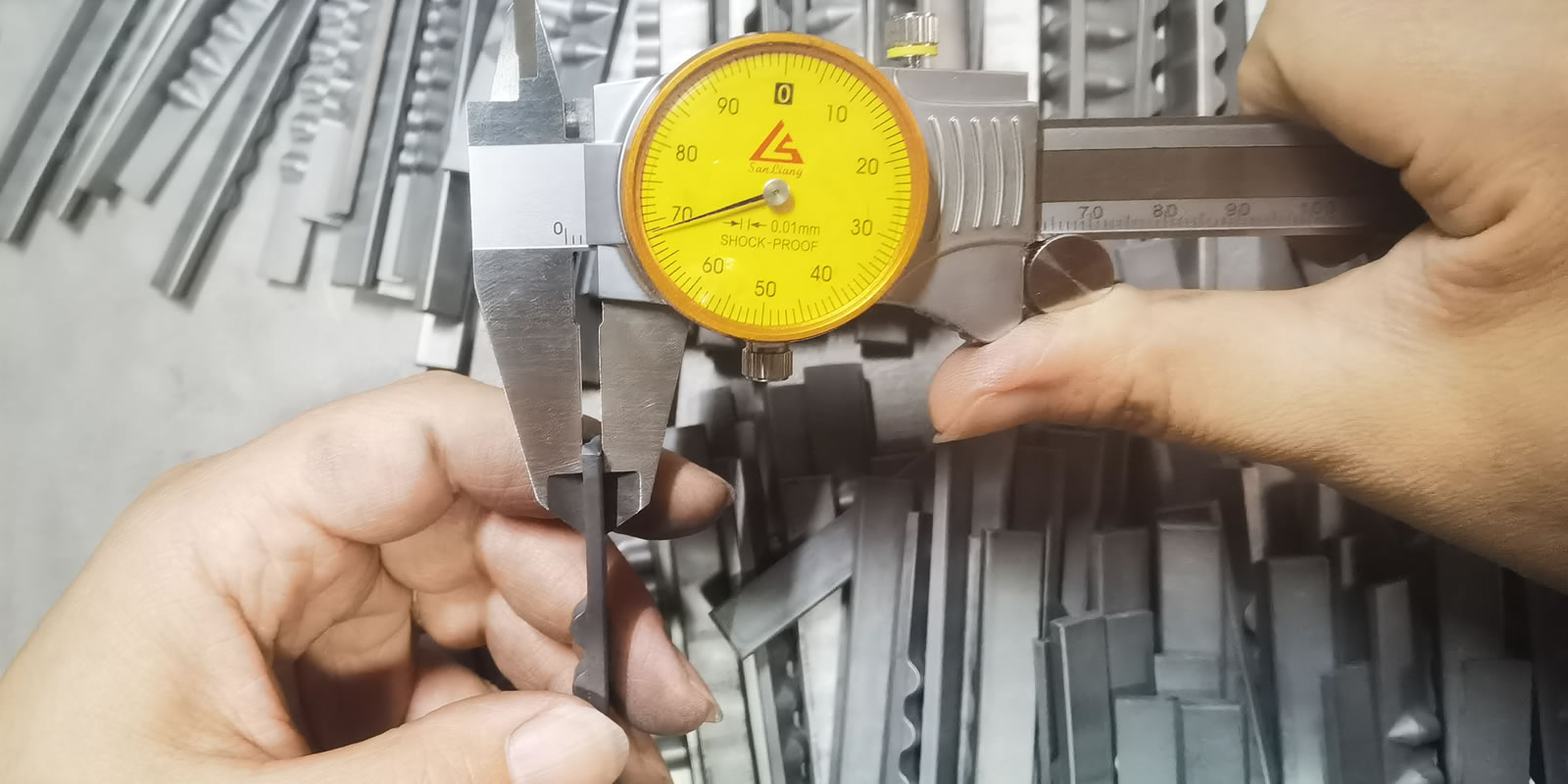

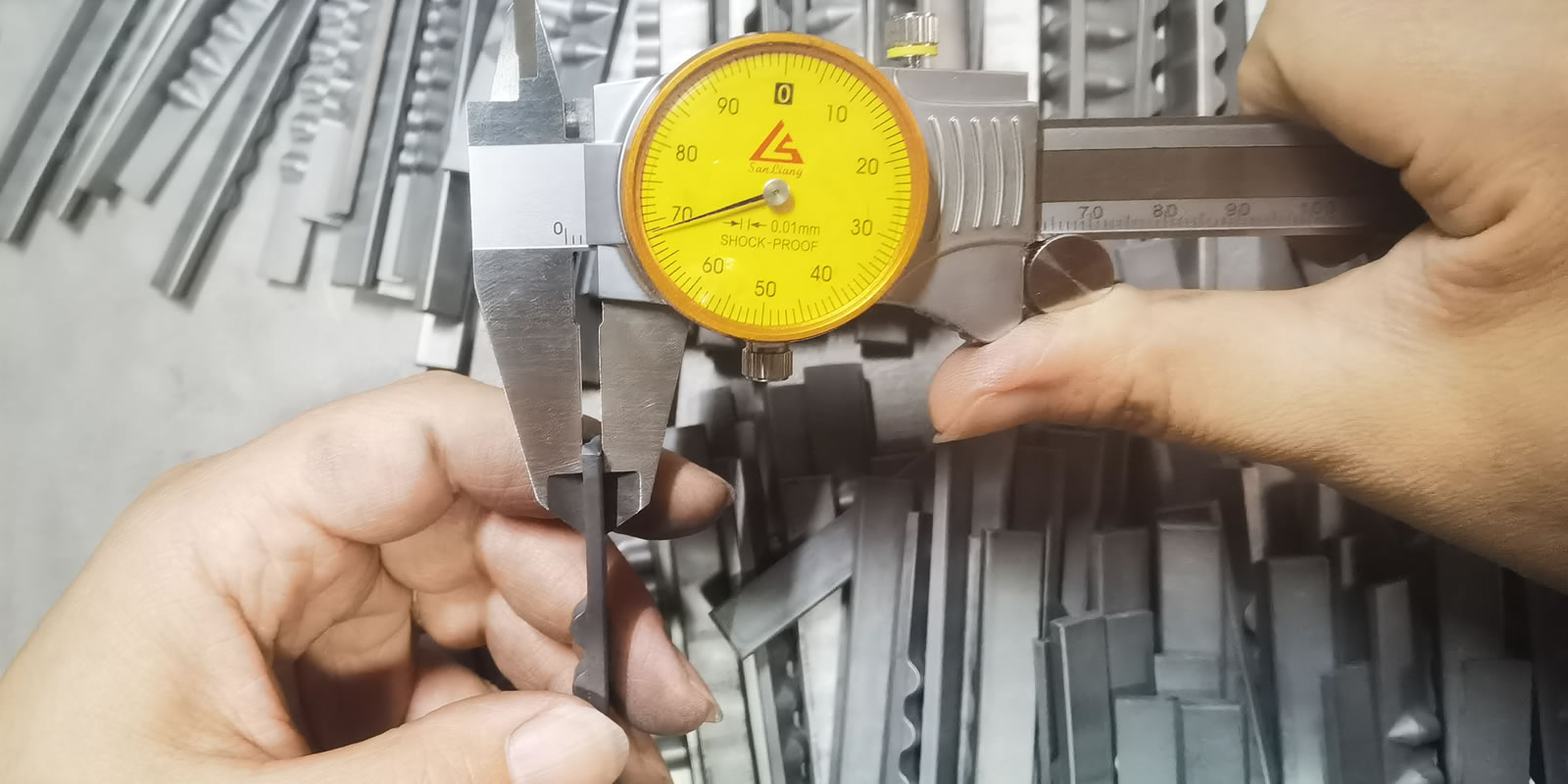

Products to be tested:

Products being tested:

Packings:

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factories & Exhibitions

CONTACT US

Phone&Wechat&Whatsup: +8618707335571

Inquiry:info@retopcarbide.com