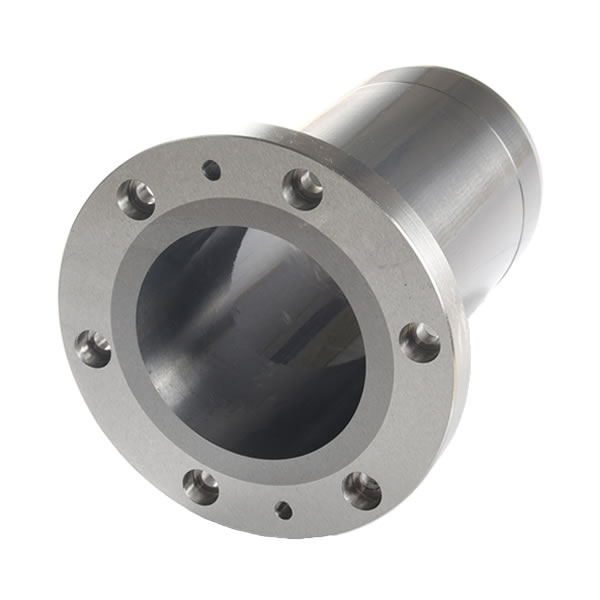

Product Name:Carbide bushing steel case for pump industry

Description:

Introducing Our Tungsten Carbide Bushings with Steel Case: Unrivaled Durability and Performance for the Pump Industry!

At Retop Carbide, we are proud to present our Tungsten Carbide Bushings with a steel case, engineered to revolutionize the pump industry. Designed for ultimate durability and unparalleled performance, our bushings combine the exceptional wear resistance of tungsten carbide with the strength of a steel outer casing.

Unmatched Durability:

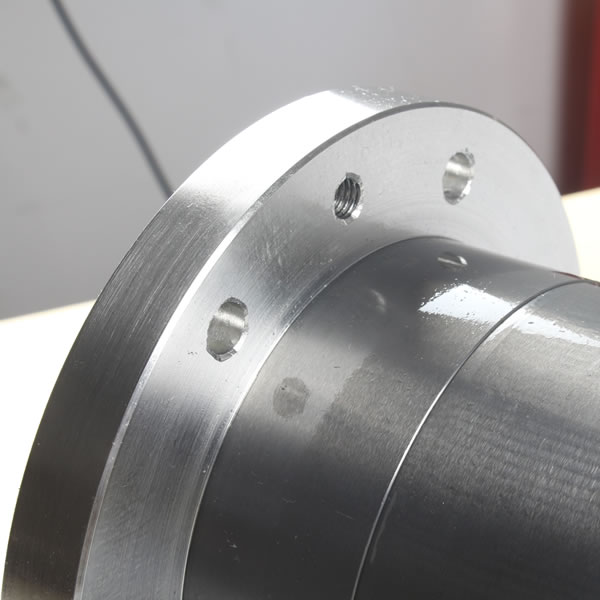

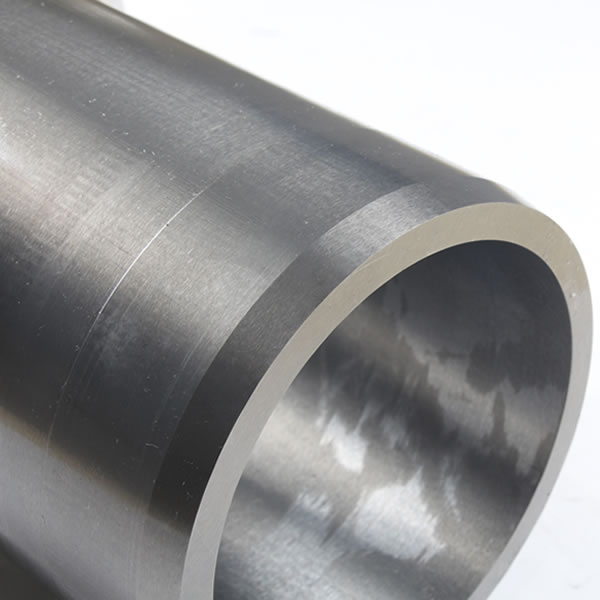

Our Tungsten Carbide Bushings are built to withstand the toughest conditions encountered in the pump industry. The inner size, composed of high-quality tungsten carbide, exhibits extraordinary hardness and wear resistance. This ensures superior resistance to abrasion, erosion, and corrosion, significantly extending the lifespan of the bushing. The outer steel case provides an added layer of strength, reinforcing the bushing's durability and enhancing its overall performance.

Optimal Performance:

Performance is at the core of our Tungsten Carbide Bushings. Engineered to deliver optimal performance, they excel even under high-pressure and high-speed operating conditions. The remarkable hardness and dimensional stability of tungsten carbide minimize friction, reducing energy loss and maximizing pump efficiency. Experience smoother operation, reduced maintenance, and improved productivity with our innovative bushings.

Resistant to Extreme Conditions:

Pump applications often involve exposure to harsh chemicals, abrasive fluids, and extreme temperatures. Our Tungsten Carbide Bushings are specifically designed to thrive in such challenging environments. The corrosion-resistant properties of tungsten carbide ensure long-term reliability and consistent performance. The steel casing provides additional protection against external forces, safeguarding the bushing from damage. From handling corrosive fluids to abrasive slurries and high-temperature applications, our bushings are engineered to excel.

Precision Engineering:

Precision is our priority. Each Tungsten Carbide Bushing is meticulously engineered to meet stringent tolerances, ensuring a perfect fit within your pump system. The inner tungsten carbide core is precisely machined for optimal performance and longevity. The outer steel casing is expertly crafted to provide structural integrity and facilitate seamless installation. Trust in our commitment to precision engineering to deliver bushings of the highest quality and reliability.

Sustainable and Cost-Effective Solution:

Our Tungsten Carbide Bushings offer a sustainable and cost-effective solution for the pump industry. With exceptional durability and wear resistance, they reduce the frequency of replacements, resulting in cost savings and minimized downtime. Moreover, their resistance to wear and corrosion ensures a longer service life, promoting sustainability and reducing environmental impact. Embrace a solution that aligns with your goals of efficiency, cost-effectiveness, and environmental responsibility.

Elevate Your Pumping Systems:

Unlock the full potential of your pumping systems with our Tungsten Carbide Bushings. Visit our website [insert website link] to discover more about our innovative solutions and how they can elevate your operations. As a special offer for our valued customers, use the code PUMP10 at checkout to enjoy an exclusive 10% discount. It's time to enhance your pumping systems with a bushing solution that sets new industry standards.

Join the Pumping Revolution:

Stay up to date with the latest developments in the pump industry by following our LinkedIn page. Explore industry insights, success stories, and updates on our Tungsten Carbide Bushings. Together, let's lead the revolution in the pump industry, redefining durability, reliability, and performance with our exceptional bushings.

Packaging:

#TungstenCarbideBushings #SteelCase #PumpIndustry #Durability #OptimalPerformance #PrecisionEngineering

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factories & Exhibitions

CONTACT US

Phone&Wechat&Whatsup: +8618707335571

Inquiry:info@retopcarbide.com