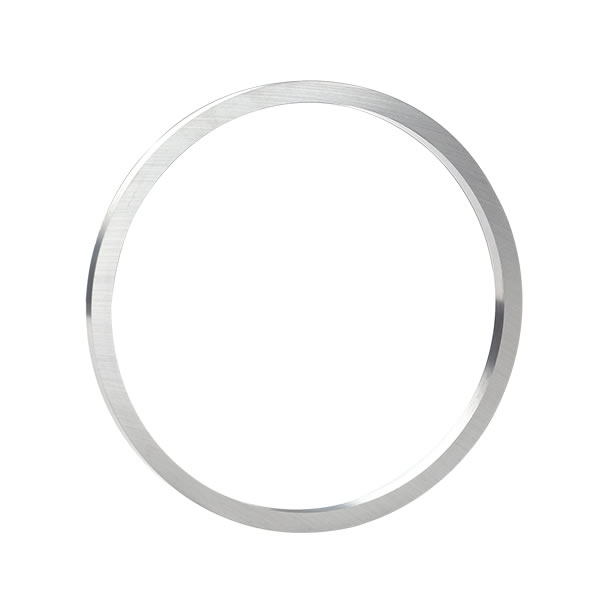

Product Name:Corrosion Resistant Mechanical Carbide Seal Ring

Description:

Corrosion Resistant Mechanical Carbide Seal Ring - a reliable and high-performance solution to enhance the efficiency and longevity of your machinery. This seal ring is meticulously engineered using top-grade carbide materials, ensuring exceptional durability and resistance to wear and tear.

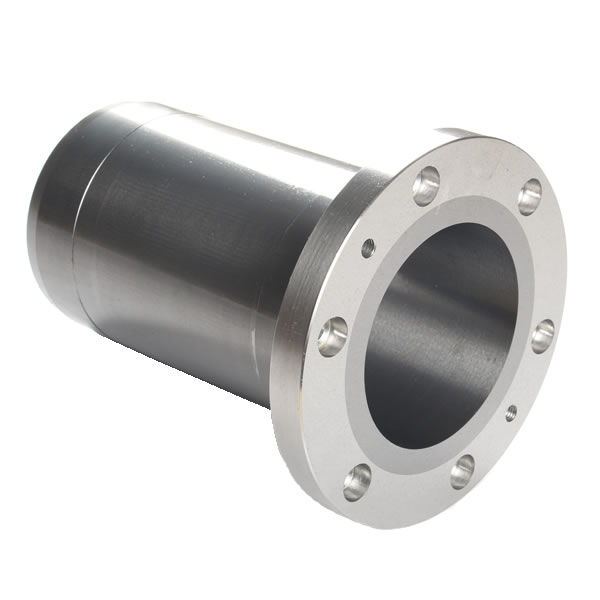

Designed for a wide range of applications, our Mechanical Carbide Seal Ring is a versatile component that excels in various industries, including automotive, manufacturing, oil and gas, and more. It is specifically engineered to provide a reliable sealing mechanism, preventing leakage and maintaining optimal performance in demanding environments.

Grade Chart for Mechanical Rings:

Grade |

Nickel

Content

Ni% |

Density

g/cm³ |

Hardness

(HRA) |

TRS

(MPa) |

Grain Size

(um) |

| YN6 | 6.0 | 14.82 | 92.0 | 2150 | 0.8 |

| YN8 | 8.0 | 14.80 | 91.5 | 2200 | 0.8 |

| YN10 | 10.0 | 14.60 | 90.5 | 2350 | 0.8 |

| YN14 | 14.0 | 14.15 | 88.8 | 2300 | 1.0 |

| YN20 | 20.0 | 14.10 | 88.5 | 2400 | 0.8 |

Key Features:

Superior Durability: Crafted from premium carbide materials, our seal ring exhibits outstanding strength and resilience, enabling it to withstand high pressures, extreme temperatures, and abrasive conditions. It ensures long-lasting performance, minimizing downtime and reducing maintenance costs.

Enhanced Sealing Efficiency: The precise design and engineering of our Mechanical Carbide Seal Ring guarantee an effective sealing mechanism. It provides a tight and secure seal, preventing the leakage of fluids, gases, or contaminants, and promoting efficient operation and optimal performance.

Versatile Applications: Our seal ring is suitable for a wide range of machinery and equipment, including pumps, compressors, turbines, engines, and more. Its adaptability and compatibility make it an ideal choice for various industrial applications, ensuring seamless integration and optimal functionality.

Customizable Options: We understand that every project has unique requirements. Hence, we offer customizable options for our Mechanical Carbide Seal Ring, allowing you to select the dimensions and specifications that best suit your specific needs. Our team of experts is ready to assist you in tailoring the seal ring to meet your exact requirements.

Easy Installation and Maintenance: Our seal ring is designed for ease of installation and maintenance, enabling smooth integration into your existing machinery. With proper care and periodic maintenance, it ensures long-term reliability and optimal performance.

Upgrade your machinery with our Mechanical Carbide Seal Ring and experience enhanced sealing efficiency, extended operational life, and reduced maintenance requirements. Trust in the durability and exceptional performance of our product to safeguard the integrity of your equipment, promote efficiency, and minimize downtime.

Contact us today to discuss your specific requirements and let our knowledgeable team guide you in selecting the perfect Mechanical Carbide Seal Ring for your machinery. Elevate your performance and reliability with our high-quality seal ring solution.

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factories & Exhibitions

CONTACT US

Phone&Wechat&Whatsup: +8618707335571

Inquiry:info@retopcarbide.com